5G Private Wireless Network Design for a Smart Factory

Precisely planned, optimised and validated a 5G Private Wireless Network design for a Smart Factory in Japan.

Overview

Since the Japanese government launched the Connected Industries strategy to support smart factories, our local strategic partner, Marubun have received requests from large manufacturing companies to aid the development of wireless connectivity within their factories.

To support the connectivity requirements of technologies such as IoT sensors, machine-to-machine (M2M) communications, AI robots and automated guided vehicles (AGV), a Private Wireless Network is needed to deliver the dedicated connectivity for low latency, reliability and security.

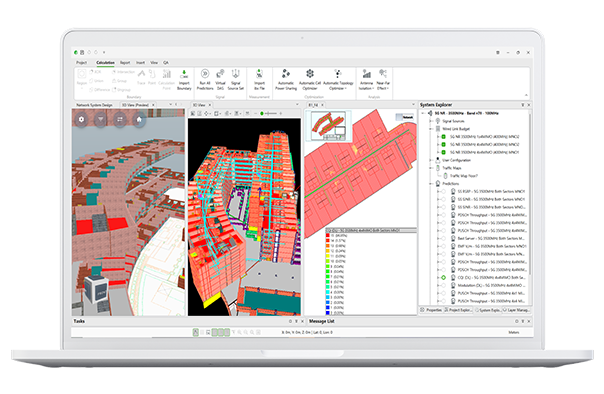

Marubun supplied Sumitomo Shoji Machinex with the Ranplan Professional network planning software to design and optimise a 5G Private Wireless Network across a 20,000-square-meter smart factory for steel and non-ferrous metal manufacturing conducted by the Sumitomo Corporation.

Challenge

A reliable wireless network connection is required to maintain the seamless production process, however a factory environment creates some RF challenges.

A typical indoor factory is filled with machinery made from metal and steel which is not friendly to wireless communications. The solid materials reflect or diffract wireless signals making it challenging to plan a network that will bypass these obstacles.

The equipment installed in factories often comes with its own wireless connection or Wi-Fi access point and when you install tens or hundreds of machines inside a building, it creates a very densely populated wireless environment which can cause interference and put a strain on the network. Ultimately this can lead to poor network performance and costly production delays.

Each Smart Factory is laid out differently and with so many technologies available, it can be difficult to determine which components and configurations are best suited for the unique environment.

Solution

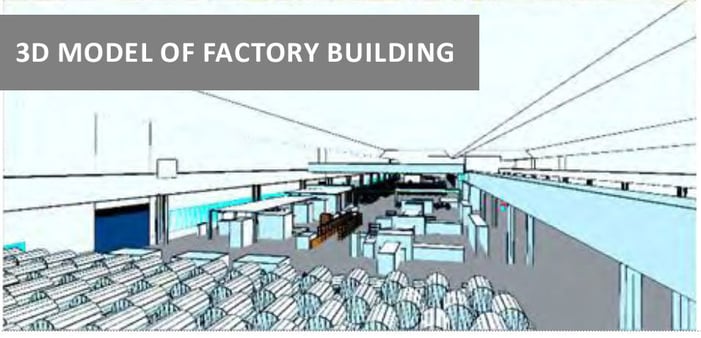

To overcome the challenges of machinery and steel materials affecting the signal propagation, Sumitomo Shoji Machinex, the company responsible for the network design, used Ranplan Professional to create a digital 3D model of the environment using information from a site survey. The efficient modelling capability enabled them to model all aspects of the smart factory, including the machinery.

All structures and machinery were assigned material information from Ranplan’s building materials library to accurately depict the impact on RF propagation, noting that physical objects naturally reflect or diffract wireless signals.

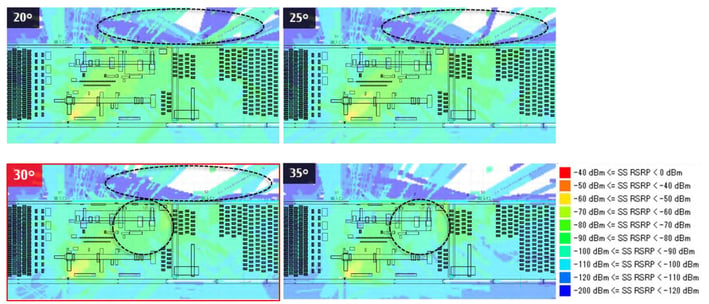

The 3D RF propagation simulations of the 20,000 square metre Smart Factory provided significant advantages when determining the number of base stations required, the preferred locations and the appropriate antenna tilt, with proper attention paid to vital restrictions on where the base stations could be installed.

Results

Sumitomo Shoji Machinex calibrated the accuracy of the simulations by importing onsite measurement data. The simulations were performed under a variety of conditions such as opened and closed factory shutters to see how this would impact the signal propagation. This helped to investigate the cause of signal loss in certain areas of the building and ascertain the appropriate tilt angle of the antennas to maximise coverage performance and minimise signal leakage.

"Ranplan Professional provides our customers with an all-in-one independent network planning platform which is leading the way companies design and maintain their local 5G networks. The ability to precisely model the unique environments and optimise the network designs with the use of 3D RF simulations and productivity-enhancing automation tools has delivered and will continue to deliver substantial time and cost savings for our customers.”

Shun Miyamoto, Information and Communications Team, Marubun

Learn how Ranplan streamlines wireless network design for enterprise buildings, boosting connectivity and efficiency